| Resolution |

18μm |

| Board Size |

50×60 – 460x500mm, 2×2.4 – 18x20in. |

| Board Thickness |

0.6 – 3.2mm, 24 – 126mils |

| Board Warp |

+/-2mm, 79mils |

| PCB Clearance |

Top: 40mm, 1.57in. Bottom: 40mm, 1.57in. |

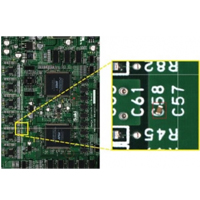

| Rotated Component Support |

Available for 0 – 359°rotation (unit of 1°) |

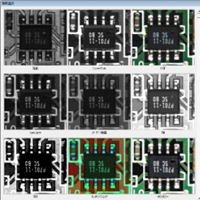

| Inspection Categories +++++ |

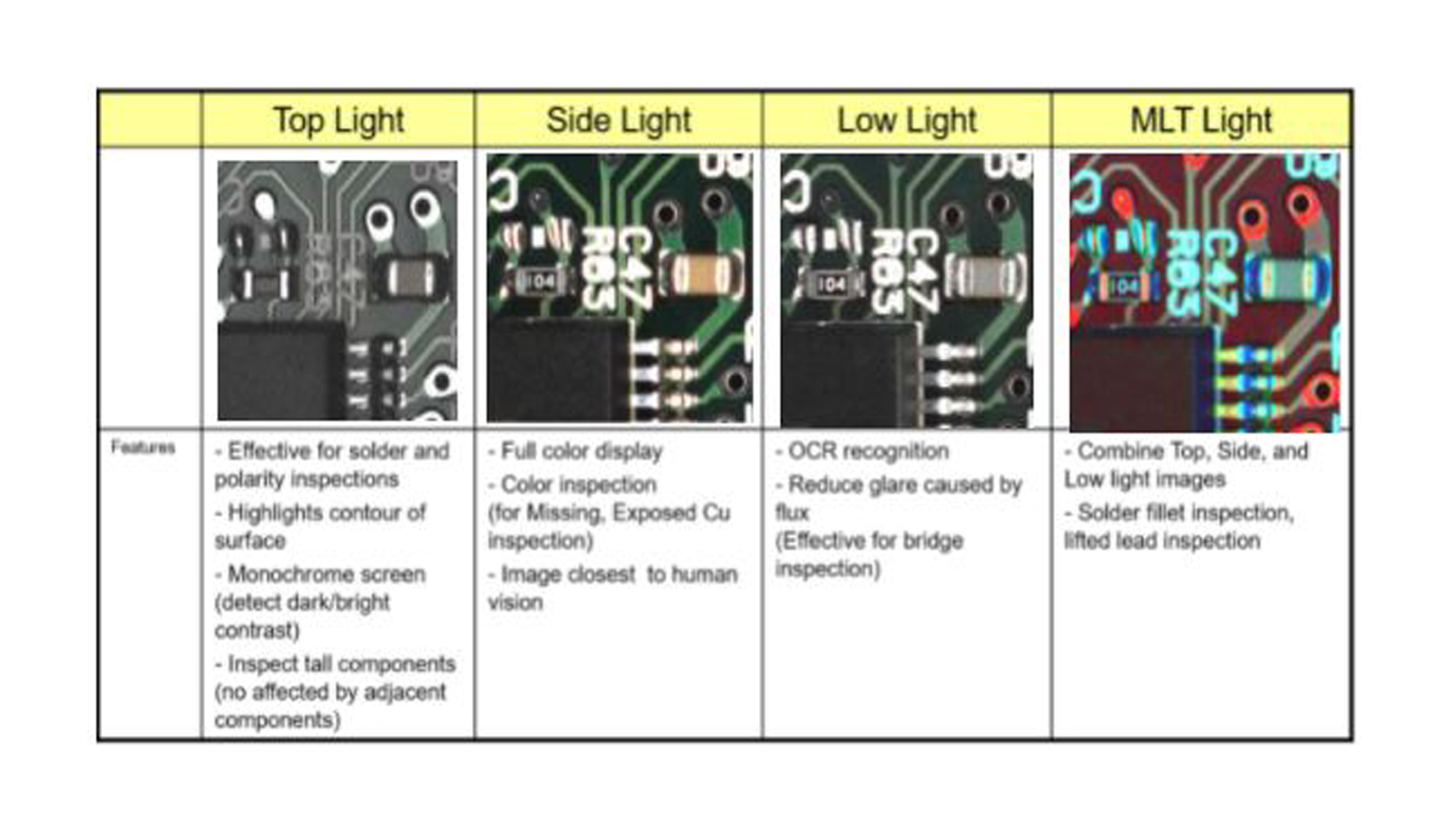

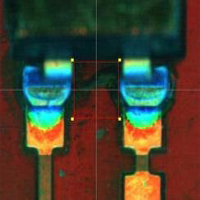

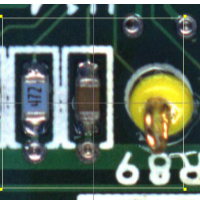

Presence/Absence, Misalignment, Tombstone, Reverse, Polarity, Bridge, Foreign material, Absence of solder, Insufficient solder, Lifted lead, Lifted Chip, and Fillet defect. Each defect name can be changed freely by system function. |

| Tact Time |

Approx. 21sec. (460x500mm) |

| Image Scanning Time |

Approx. 10sec. (460x500mm) |

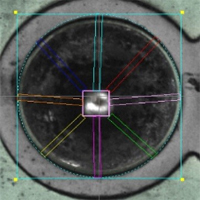

| Camera (Image Processing) |

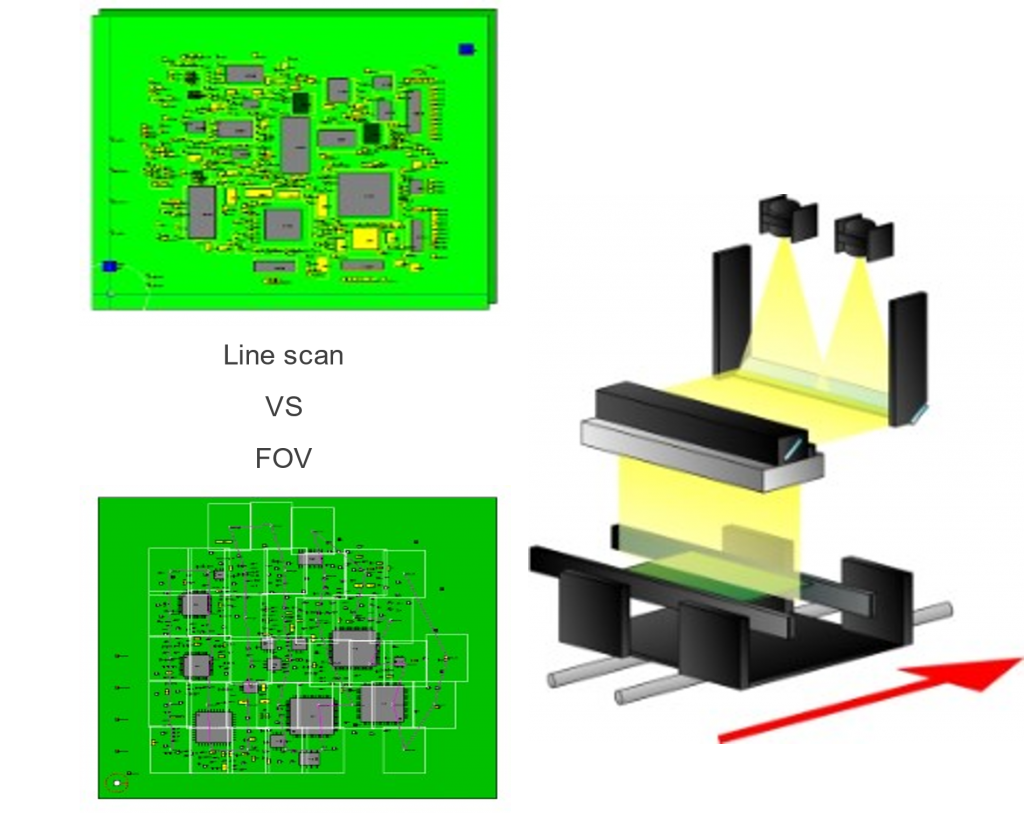

Line color CCD camera |

| Lighting |

LED lighting system |

| Transfer Conveyor Method |

Flat belt transfer |

| Transfer Conveyor Height |

900+/-20mm, 36+/-0.8in |

| Transfer Conveyor Width Adjustment |

Automatic |

| Operating System |

Windows XP English Version |

| Optional System |

BF-Editor / BF-RP1 / BF-Monitor / BF-View |

| Optional |

2D Barcode Recognition, Journal Printer |

| Installation Specifications |

|

| Electric Power Requirement Single Phase |

Single Phase~100 – 120V / 200 – 240V +/-10%,50/60Hz, 750VA |

| Power Consumption |

750VA |

| Air Requirement |

0.5MPa, 5L/min (ANR), 73PSI, 0.18CFM |

| Usage Environment |

15°C(59F) – 30 °C(86F) / 15 – 80% RH (Non-condensing) |

| Noise Level |

58.3dB |

| Dimensions |

Flat belt transfer850x 1340 x 1230mm,

34 x 53 x 49in. |

| Weight Approx. |

Approx. 450kg, 992lbs |