Tabletop 2DAOI Sirius/Comet

BF-Comet and BF-Sirius Benchtop High Resolution, High Speed Automated Optical Inspection Systems

Key Features

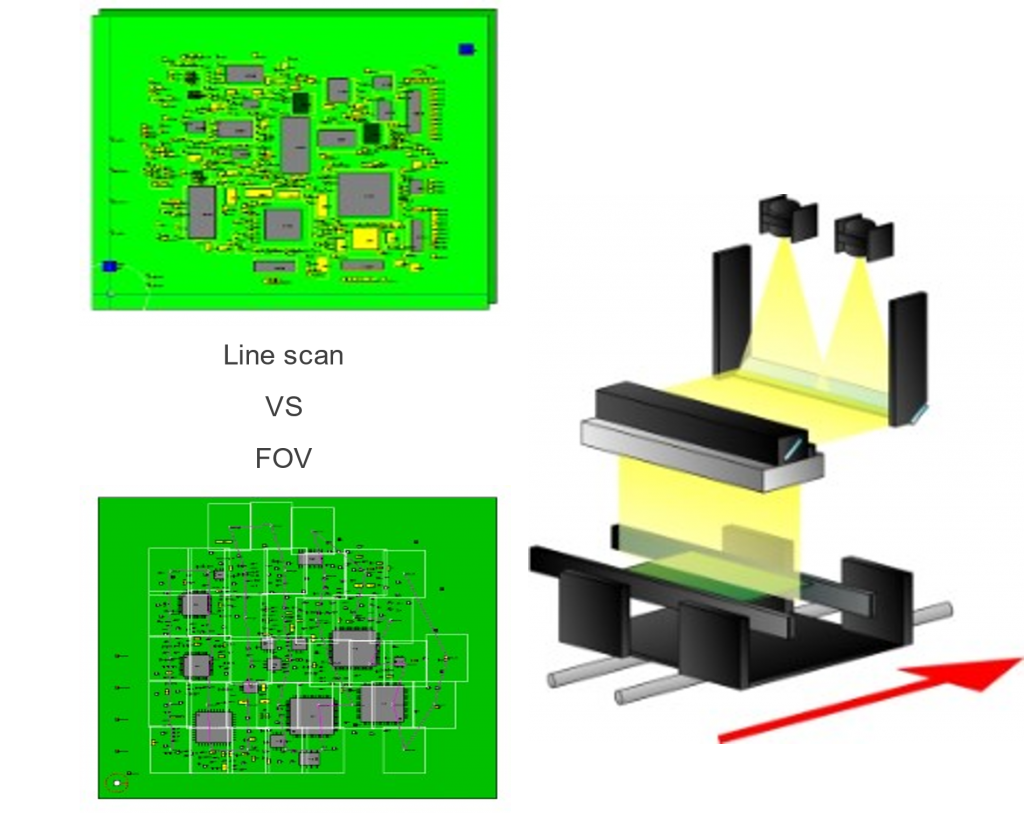

- Line Scan Visual Inspection

- Resolution -10μm/18 μm

- Line-Ups for Flexible Use

- High Throughput

- Easy Programming

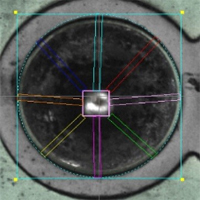

- Saki’s Innovative Coaxial Top Light

- Compact, Long-life Design

- Traceability

- Only one direction of movement, board is kept stable through machine

- No shaking of system due to camera movement

SAKI’s Unique Line Scanning Technology

- Line scan technology is the core technology of Saki AOI。

- Use this technology can scan PCB image about 10 second. To meet high speed inspection.

- Normal AOI use FOV type. The inspection speed depends on component quantity. When the quantity of component increases the inspection time will increase more.

- Line scan technology use line sensor camera to scan the whole board image. The speed will not affect by component quantity.

- The scan image will storage at PC memory (Free memory) and direct make inspection at memory.

- It can finish all inspection at 20~30 second

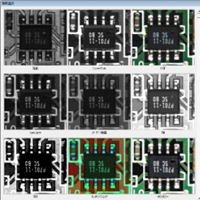

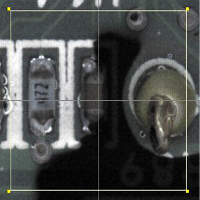

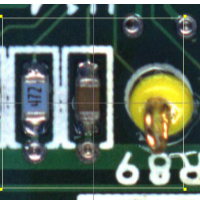

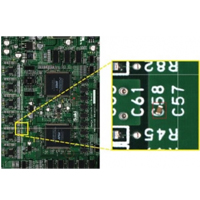

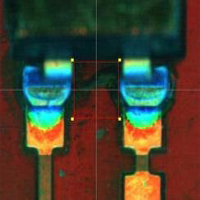

Application Images

Technical Data

BF-Comet 10/18

BF-Sirius

BF-Comet 10/18

| BF-COMET 10/18 |  |

| Resolution | 10μm (BF- Comet10) 18μm (Bf Comet18) |

| Board Size | 50×50 – 250×330mm, 2×2 – 10×13in. |

| Board Thickness | 0.6 – 2.5mm, 24 – 100mils |

| Board Warp | +/-2mm, 79mils |

| PCB Clearance | Top: 40mm, 1.57in. Bottom: 60mm, 2.36in. |

| Rotated Component Support | Top: 40mm, 1.57in. Bottom: 60mm, 2.36in. |

| Inspection Categories | Presence/Absence, Misalignment, Tombstone, Reverse, Polarity, Bridge, Foreign material, Absence of solder, Insufficient solder, lifted lead, Lifted Chip, and Fillet defect. Each defect name can be changed freely by system function. |

| Tact Time | Approx. 18 sec. Approx. 13sec. |

| Image Scanning Time | Approx. 11sec. Approx. 7sec. |

| Camera (Image Processing) | Line color CCD camera |

| Lighting- | LED lighting system |

| Operating System | Windows XP English Version |

| Optional System | BF-Editor / BF-RP1 / BF-View |

| Optional- | 2D Barcode Recognition, Journal Printer, OK/NG Signal Out |

| Installation Specifications | |

| Electric Power Requirement Single Phase | Single Phase~100 – 120V / 200 – 240V +/-10%,50/60Hz 450VA 400VA |

| Power Consumption | 450VA 400VA |

| Air Requirement- | Not needed |

| Usage Environment- | 15°C(59F) – 30°C(86F) / 15 – 80%RH (Non-condensing) |

| Noise Level | |

| Dimensions | 580 × 850 × 452mm, 22.84 × 33.47 × 17.80in |

| Weight Approx. | Approx. 83 Kg, 183lbs . 80 Kg, 177lbs |

BF-Sirius

| BF-SIRIUS |  |

| Resolution | 18μm |

| Board Size | 50×50 – 460×500mm, 2×2 – 18×20in. |

| Board Thickness | 0.6 – 2.5mm, 24 – 100mils |

| Board Warp | +/-2mm, 79mils |

| PCB Clearance | Top: 40mm, 1.57in. Bottom: 60mm, 2.36in. |

| Rotated Component Support | Available for 0 – 359°rotation (unit of 1°) |

| Inspection Categories | Presence/Absence, Misalignment, Tombstone, Reverse, Polarity, Bridge, Foreign material, Absence of solder, Insufficient solder, lifted lead, Lifted Chip, and Fillet defect. Each defect name can be changed freely by system function. |

| Tact Time | Approx. 18sec. |

| Image Scanning Time- | Approx. 10sec. |

| Camera (Image Processing) | Line color CCD camera |

| Lighting | LED lighting system |

| Operating System | Windows XP English Version |

| Optional System | BF-Editor / BF-RP1 / BF-View |

| Optional- | 2D Barcode Recognition, Journal Printer, OK/NG Signal Out |

| Installation Specifications | |

| Electric Power Requirement Single Phase- | Single Phase~100 – 120V / 200 – 240V +/-10%, 50/60Hz 700VA |

| Power Consumption | 700VA |

| Air Requirement- | Not needed |

| Usage Environment- | 15°C(59F) – 30°C(86F) / 15 – 80%RH (Non-condensing) |

| Noise Level | 60.5dB |

| Dimensions | 800 × 1280 × 600mm, 31.50 × 50.39 × 23.62in. |

| Weight Approx. | Approx. 175 kg, 386lbs |