| Temperature Range | RT ~ +60 ℃ |

| Spray volume | 1.5 ± 0.5㎖/80㎠/h |

| Atomizer | Fine fog of 5~20 micron droplet size |

| Filter/regulator | A filter cum air regulator, with pressure form 0~30 PS |

| Saturator | Non-corrosive, temperature controlled saturator, Automatic water level controller, Immersion heater |

| Input power requirements | 230V ±10%, 380V ±10%, 50Hz/60Hz, 1Ph/3Ph (Changeable according to customer specification) |

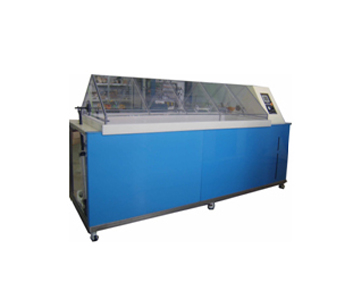

| Capacity | 200ltr/480ltr/600ltr/1000ltr Microprocessor controller including self-diagnostics, warning message function |